A universal motor is a special motor that runs on either single-phase AC (alternating current) power or a DC (direct current) supply. These motors typically have series-wound armatures and field windings, which result in strong starting torque. Most universal motors are directly integrated into the machinery designed to power. Most universal motors are designed to work at speeds greater than 3500 RPM. They run slower when powered by an AC source than when powered by a DC supply of the same voltage because of a higher voltage drop that occurs through AC supplies. Read More…

At AutomationDirect.com, we specialize in providing a wide range of electric motors and electronic enclosures to meet our customers' diverse needs. Our commitment to excellence drives us to offer top-quality products that deliver superior performance and reliability. With our extensive selection of electric motors, ranging from AC motors to DC motors and everything in between, we empower...

When reliability and power are a must, the universal motors you find at ElectroCraft can operate with high efficiency, low voltage, and at a low cost. Applications that our universal electric motors serve include robotics, packaging, automotive, and medical equipment. Electric motor products include the CompletePower™ Plus Universal Drive, complete with a user-friendly configurable interface....

Quickly rising as the world’s leading motor specialized company, SPG Motor pioneers the fractional horsepower motor market in innovation & advanced quality assurance. All of our fractional horsepower motors are ISO 9001 certified for automation equipment & appliances made by top companies like Whirlpool, Maytag & GE. For more information, contact SPG today!

Maxon Precision Motors, Inc., manufactures small, high-quality, precision DC brush and brushless motors used in medical, semiconductor, test and measurement, robotics, and manufacturing applications, among others. These advanced motors range in size from 4 to 90 mm and are available up to 500 watts. maxon also offers an extensive selection of gearheads, encoders, tachometers, and control...

When you choose Composite Motors, you gain access to a reliable and forward-thinking partner in the realm of fractional horsepower motors. Our products are designed to endure, ensuring that your systems operate at their best for years to come. Join us in embracing the power of innovation and quality, as we continue to shape the future of fractional horsepower motors together.

More Universal Motor Manufacturers

Universal motors come in two different categories- compensated and uncompensated. Compensated motors use additional, scattered-field winding to help reduce power distortion for universal motors using AC power.

Universal Motor Mechanism

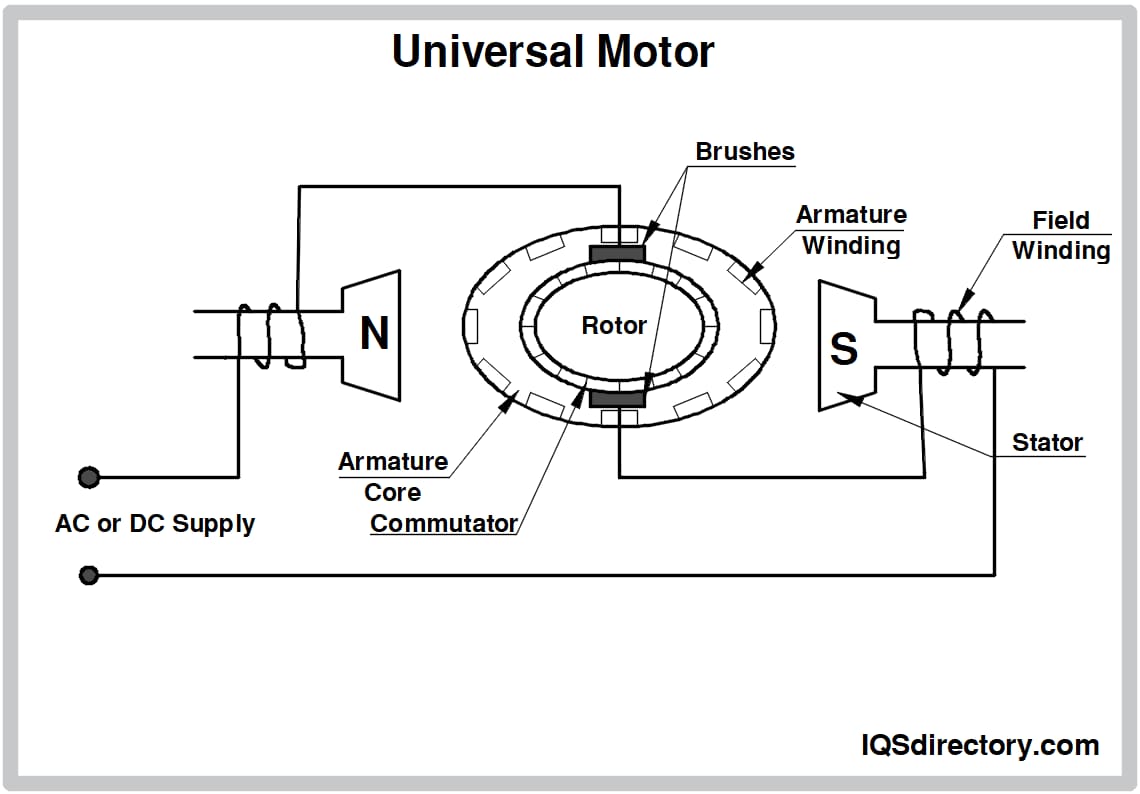

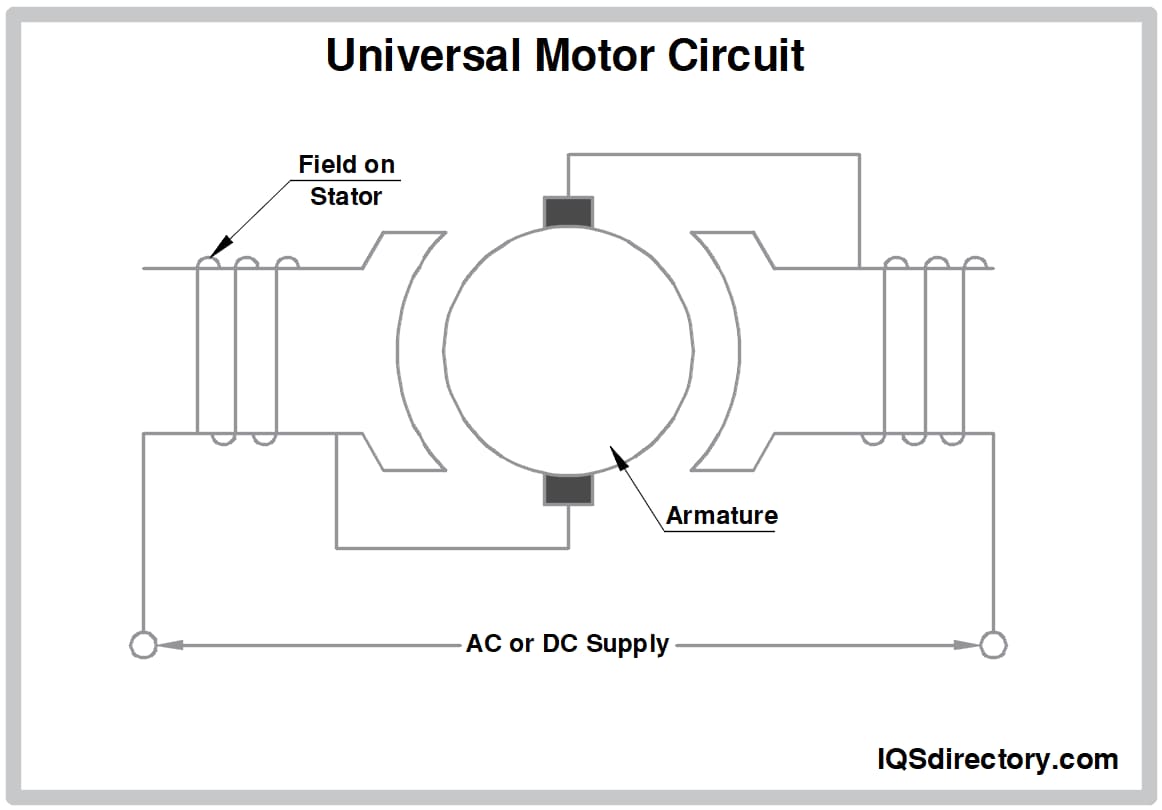

A universal motor's architecture is similar to that of a DC motor. Field poles are installed at the top of the stator. Weaved field coils are attached to the field poles. However, the stator and armature field circuits and the complete magnetic route are laminated. The rotating armature is wrapped with straight or skewed slots, and the commutator has brushes resting on it. The commutation on AC is harsher than it is for DC due to the current induced in the armature coils; hence high-resistance brushes are employed.

Due to the heating of the motor's magnetic components caused by the application of AC, typical DC motors experience eddy current losses. In addition, the motor's total efficiency is reduced due to this eddy current. Eddy current and efficiency loss from heating magnetic components are avoided in the case of universal motors, which use electromagnetic field winding in place of permanent magnets so they may operate on both power sources.

Working Principle of a Universal Motor

A universal motor can run on a single-phase AC or DC supply. The universal motor functions as a DC series motor when supplied with a DC source. A direct current produces an electromagnetic field when electricity travels through the field winding. The armature's conductors also carry the same current. A current-carrying conductor encounters mechanical force when it is in an electromagnetic field. This mechanical force, or torque, induces rotation of the rotor. The Fleming left-hand rule (make an L with your left hand, the thumb represents thrust, the middle finger represents the magnetic field, and the middle finger represents the direction of the current) is used to determine the force's direction. With AC power, it still produces a single-direction torque. The direction of the magnetic field and the direction of the armature current reverse to maintain the same direction of the force on armature conductors.

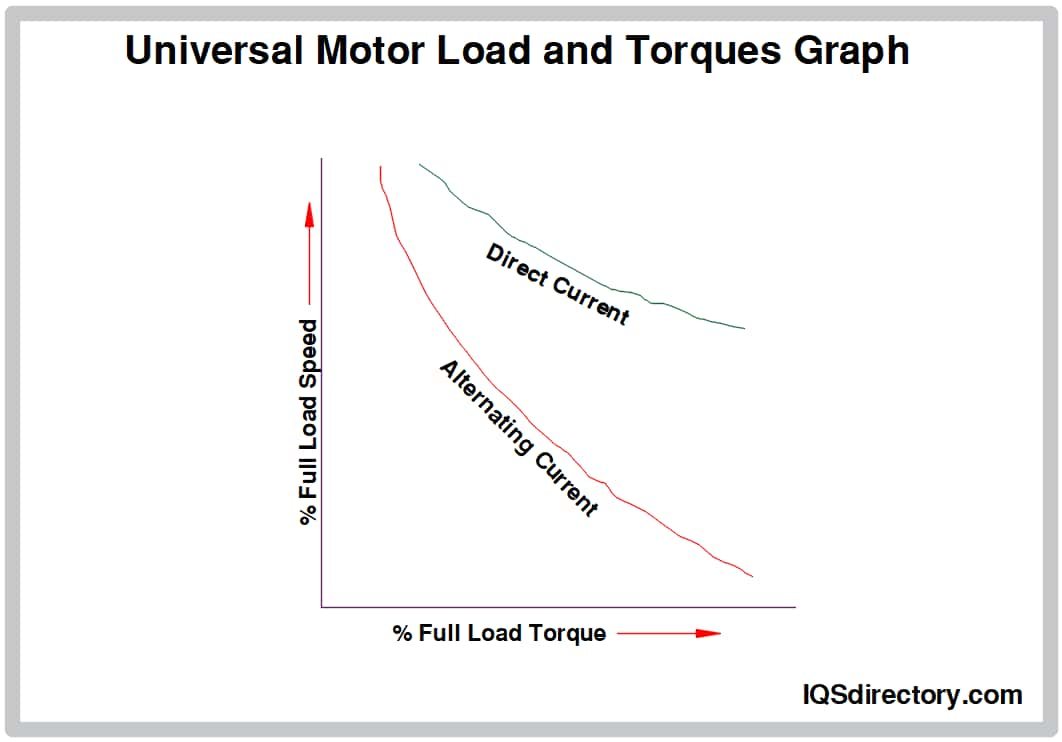

Universal Motor Speed and Load Characteristics

A universal motor's characteristics are similar to those of a DC series motor. The speed of a universal motor is very high when there is no load and very low when there is a load. Gear trains are typically utilized to achieve the desired speed on the demanded load.

Applications of Universal Motors

Numerous home appliances, such as vacuum cleaners, food, and drink mixers, domestic sewing machines, etc., employ universal motors. In addition, appliances like portable drills, blenders, and others use universal motors with higher ratings.

Benefits of Universal Motors

- Both DC and AC voltage sources can power the universal motor.

- The universal motor is less expensive when compared to other motors.

- The field and armature winding are built in sequence, allowing them to rotate at a very high speed, between 3.6K rpm and 25K rpm, just like series DC motors. Because of this, they can be employed in situations where quick rotations are required.

- Due to its small and lighter weight, the universal motor is utilized in many portable equipment devices requiring compact size.

- Power ratings for universal motors can be very high, ranging from 5W (watt/s) to 500W. The universal motor is utilized in mobile drill machines and blenders due to its higher rating and small size.

Disadvantages of Universal Motors

- Comparatively speaking to other AC and DC motors, like induction motors, universal motors produce more noise. Noise levels climb as the speed of the universal motor increases.

- The universal motor must be carefully balanced for it to operate as intended. Strong vibrations caused by even a slight imbalance may affect its ability to function properly and could eventually endanger anyone in the vicinity.

- Unlike DC motors, the universal motor is difficult to reverse its power connection such that it runs in the opposite direction and only on AC power.

- Universal motors are built similarly to series DC motors. Since a very high current will flow without any load, the motor may reach an unsafely high speed like a series DC motor. Therefore, the universal motor needs to have some load for effective speed control to be provided at startup. To accomplish this, universal motors must include a fan attached to the rotor shaft to add some load to the motor and make it more tolerant of the no-load condition, which prevents a runaway, high-speed condition.

Choosing the Correct Universal Motor Manufacturer

To ensure you have the most beneficial outcome when purchasing a universal motor from a universal motor manufacturer, it is important to compare several companies using our directory of universal motor manufacturers. Each universal motor manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each universal motor business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple universal motor businesses with the same form.

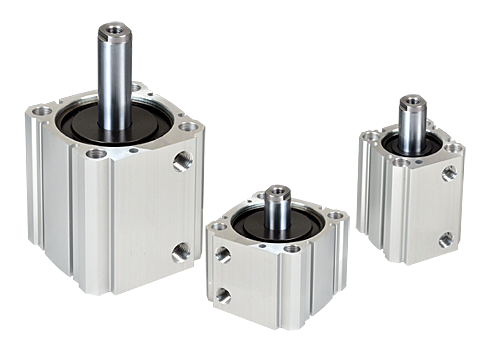

Air Cylinders

Air Cylinders Assembly Machinery

Assembly Machinery Ball Bearings

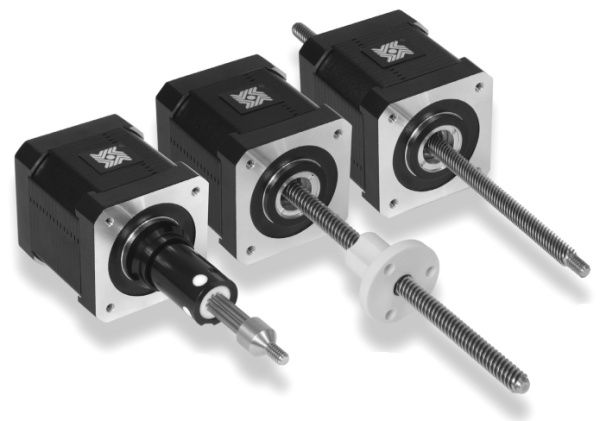

Ball Bearings Electric Motors

Electric Motors Fractional Horsepower Motors

Fractional Horsepower Motors Friction Materials

Friction Materials Linear Actuators

Linear Actuators Linear Bearings

Linear Bearings Linear Slides

Linear Slides Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services