Permanent magnets are most commonly used in applications requiring constant magnetic force, making them ideal for electric motors. Often manufactured as fractional horsepower motors, permanent magnet motors typically run on a horsepower (HP) of 1 or less, such as ½ HP or ¼ HP. Able to be utilize alternating current (AC) or direct current (DC) electrical flow, permanent magnet motors can have a frame size of 42, 48 or 56, as defined by standards put in place by the National Electrical Manufacturers Association (NEMA). Read More…

Since 1963, Dart Controls has been designing and manufacturing some of the world’s most reliable variable speed motor drives, controls and accessories for electric motors. Through continuous innovation, a relentless dedication to the industry, and a commitment to high quality products and dependable delivery Dart Controls has retained the leadership position it established over 60 years ago.

When reliability and power are a must, the universal motors you find at ElectroCraft can operate with high efficiency, low voltage, and at a low cost. Applications that our universal electric motors serve include robotics, packaging, automotive, and medical equipment. Electric motor products include the CompletePower™ Plus Universal Drive, complete with a user-friendly configurable interface....

American Electric Motors is a full service shop offering total sales & repair service, from A.C. motors, pump motors & servo motors to 5,000 H.P. D.C. motors. We stock & sell all types of new motors, pumps & brakes, plus our large inventory of used & remanufactured electric motors can save you thousands.

For custom-designed and -manufactured gear motors, contact us. We’ve been doing this business since 1958. So, for either permanent magnet AC motors or shaded pole induction DC motors, we’re the ones to get in touch with. Our website contains a downloadable motor design sheet—we welcome you to use it.

When you choose Composite Motors, you gain access to a reliable and forward-thinking partner in the realm of fractional horsepower motors. Our products are designed to endure, ensuring that your systems operate at their best for years to come. Join us in embracing the power of innovation and quality, as we continue to shape the future of fractional horsepower motors together.

More Permanent Magnet Motor Manufacturers

Permanent magnetic motors are used in a wide range of applications, and industries that benefit from them include: automotive, for use in window wipers, powered seats, central locking systems and more; industrial, in pumps, conveyors, extruders and other processing, manufacturing and assembly equipment; HVAC, in systems and equipment such as fans and blowers; and construction, for heavy-duty materials handling equipment such as cranes and hoists.

Permanent magnet motors are typically separated into two main types based on design and electrical flow: brushless DC motors and permanent magnet synchronous motors. While both types are types of synchronous motors, meaning that the rotor rotates at the same speed as the magnetic field, a brushless DC motor is unique in that it operates based on DC, while most synchronous motors operate on AC, and that it has an electronic commutation system instead of a mechanical one.

Permanent magnet synchronous motors, on the other hand, are run on AC as is typical and induction is not required for magnetic field production. Both are designed in a similar style, with the basic components of an enclosure, rotor, axle, wound armature and permanent magnet. Also referred to as a coil, the wound armature rotates while the magnetic field remains stationary.

The rotation results from the magnet's reaction when the electrical current flows through specific points of the motor. One major difference in design between the two types of motors is that brushless DC motors have a trapezoidal-shaped back electromotive force (EMF) while permanent magnet synchronous motors have a sinusoidal-shaped back EMF. Back EMF refers to the voltage that is induced in the wound armature when the motor is rotating.

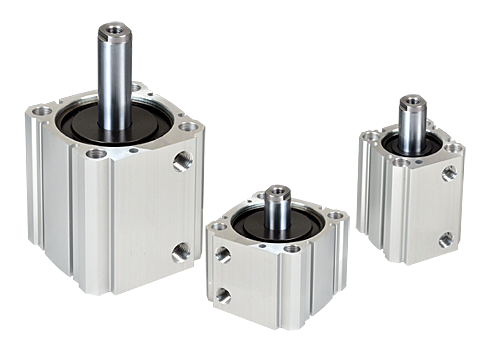

Air Cylinders

Air Cylinders Assembly Machinery

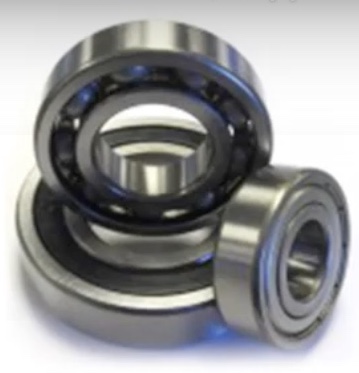

Assembly Machinery Ball Bearings

Ball Bearings Electric Motors

Electric Motors Fractional Horsepower Motors

Fractional Horsepower Motors Friction Materials

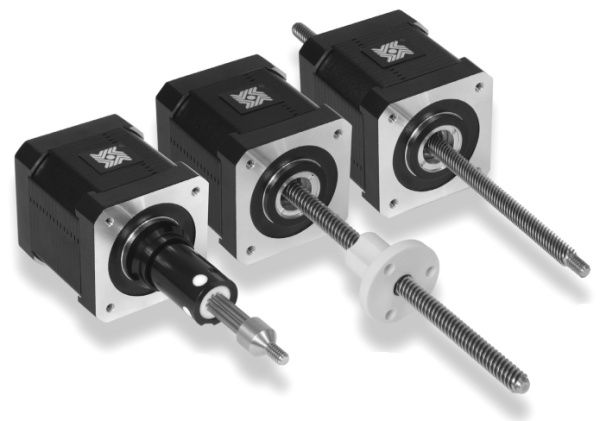

Friction Materials Linear Actuators

Linear Actuators Linear Bearings

Linear Bearings Linear Slides

Linear Slides Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services