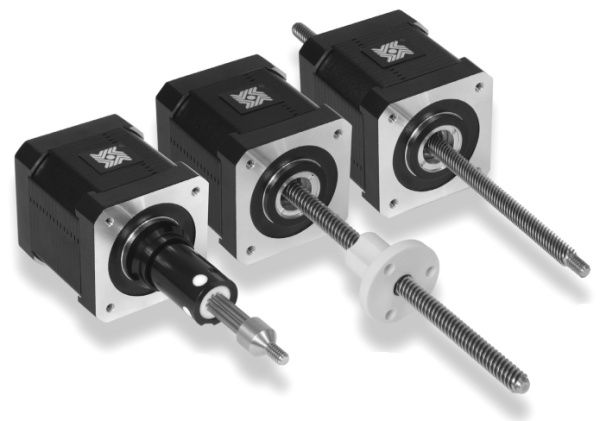

A stepper motor is an electrical motor, as shown in the figure below. The shaft protruding out of the motor is attached to a rotor that rotates following the concept of electromagnetism. This converts electrical energy into mechanical energy. Without the need for any sensor, the angular position of the shaft can be determined accurately by counting the rotation steps. Read More…

At AutomationDirect.com, we specialize in providing a wide range of electric motors and electronic enclosures to meet our customers' diverse needs. Our commitment to excellence drives us to offer top-quality products that deliver superior performance and reliability. With our extensive selection of electric motors, ranging from AC motors to DC motors and everything in between, we empower...

When reliability and power are a must, the universal motors you find at ElectroCraft can operate with high efficiency, low voltage, and at a low cost. Applications that our universal electric motors serve include robotics, packaging, automotive, and medical equipment. Electric motor products include the CompletePower™ Plus Universal Drive, complete with a user-friendly configurable interface....

Quickly rising as the world’s leading motor specialized company, SPG Motor pioneers the fractional horsepower motor market in innovation & advanced quality assurance. All of our fractional horsepower motors are ISO 9001 certified for automation equipment & appliances made by top companies like Whirlpool, Maytag & GE. For more information, contact SPG today!

Maxon Precision Motors, Inc., manufactures small, high-quality, precision DC brush and brushless motors used in medical, semiconductor, test and measurement, robotics, and manufacturing applications, among others. These advanced motors range in size from 4 to 90 mm and are available up to 500 watts. maxon also offers an extensive selection of gearheads, encoders, tachometers, and control...

When you choose Composite Motors, you gain access to a reliable and forward-thinking partner in the realm of fractional horsepower motors. Our products are designed to endure, ensuring that your systems operate at their best for years to come. Join us in embracing the power of innovation and quality, as we continue to shape the future of fractional horsepower motors together.

More Stepper Motor Manufacturers

What is a Stepper Motor?

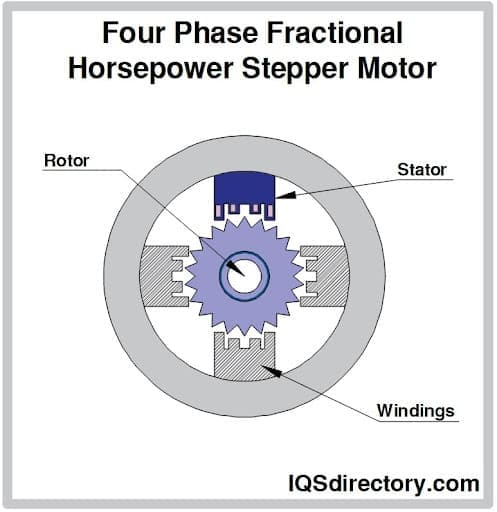

A stepper motor is an electrical motor, as shown in the figure below. The shaft protruding out of the motor is attached to a rotor that rotates following the concept of electromagnetism. This converts electrical energy into mechanical energy. Without the need for any sensor, the angular position of the shaft can be determined accurately by counting the rotation steps.

Steppers motors are available in a variety of sizes and materials to best suit the applications. As the name implies, the stepper divides one full rotation into smaller, equal rotations, also known as steps. This feature enables users to program it into moving only certain degrees hence controlling the motion.

Stepper Motors Operational Theory

Like all electric motors, stepper motors also consist of two main components. One is the stator which is a non-movable part. The other one is a movable part called a rotor. The rotor is usually a permanent magnet. It is encased by a stator. There are bar/teeth like structures on the stator which provide support for the coil, as shown in the figure below.

The stepper motor operates by generating the magnetic field in one of the stators. It is done by supplying electric current through the coil around the stator. The rotor moves towards the charged stator. The alternating current passing through the coil produces a magnetic field around the rotor. As a result, the rotor moves in steps depending on the magnetic field lines produced by the respective stator.

Types of Stepper Motors

The efficiency of stepper motors largely depends on how it's built. The following three types of stepper motors are based on structural differences. The type of rotor used determines the performance here.

Permanent Magnet Stepper Motor

In this type, the rotor is a permanent magnet. It easily lines up with the stator's magnetic force. This change ensures better torque production. Although it provides low speed and low resolution.

Variable Reluctance Stepper Motor

In variable reluctance motors, the rotor used is made up of an iron core. It is shaped to make it easier for the rotor to align with the magnetic field produced by stator bars. Unlike permanent magnet rotors, it produces higher speeds and resolution, but achieving better torque is impossible.

Hybrid Stepper Motor

These kinds of motors combine permanent magnet stepper motors and variable reluctance ones. It’s rotor consists of two caps made up of a permanent magnet shaped like a variable reluctance rotor. The mixture of design provides all the qualities and benefits of other motors. It has high speed, better torque, and good resolution. Since it is a hybrid and complex design, it costs more than the other stepper motors.

Benefits of Using Stepper Motors

Some of the benefits of stepper motors include:

- Stepper motors have a cleverly engineered internal structure that enables users to track angular position and rotations without sensors.

- These do not require extra maintenance.

- Unlike DC motors which do not offer good torque at less speed, stepper motors provide better torque even at lower speeds.

- Stepper motors usually are durable and have a long life.

- Precise positioning by stepper motors makes it usable in robotics and automated processes where extreme accuracy is required.

Applications of Stepper Motors

Stepper motors are different in their utilizations, yet probably the most widely recognized uses include:

- 3D printing equipment

- Textile machines

- Printing presses

- Gaming machines

- Medical imaging machinery

- Small robotics

- CNC milling machines

- Welding equipment

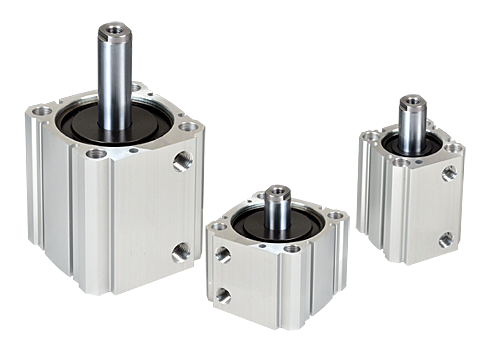

Air Cylinders

Air Cylinders Assembly Machinery

Assembly Machinery Ball Bearings

Ball Bearings Electric Motors

Electric Motors Fractional Horsepower Motors

Fractional Horsepower Motors Friction Materials

Friction Materials Linear Actuators

Linear Actuators Linear Bearings

Linear Bearings Linear Slides

Linear Slides Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services