Fractional horsepower motors are small motors that run with a power rating of less than one horsepower, or a fraction of a horsepower. Built on a frame, manufacturers simply refer to fractional horsepower motors as FHP motors. Read More…

At AutomationDirect.com, we specialize in providing a wide range of electric motors and electronic enclosures to meet our customers' diverse needs. Our commitment to excellence drives us to offer top-quality products that deliver superior performance and reliability. With our extensive selection of electric motors, ranging from AC motors to DC motors and everything in between, we empower...

When reliability and power are a must, the universal motors you find at ElectroCraft can operate with high efficiency, low voltage, and at a low cost. Applications that our universal electric motors serve include robotics, packaging, automotive, and medical equipment. Electric motor products include the CompletePower™ Plus Universal Drive, complete with a user-friendly configurable interface....

Quickly rising as the world’s leading motor specialized company, SPG Motor pioneers the fractional horsepower motor market in innovation & advanced quality assurance. All of our fractional horsepower motors are ISO 9001 certified for automation equipment & appliances made by top companies like Whirlpool, Maytag & GE. For more information, contact SPG today!

Maxon Precision Motors, Inc., manufactures small, high-quality, precision DC brush and brushless motors used in medical, semiconductor, test and measurement, robotics, and manufacturing applications, among others. These advanced motors range in size from 4 to 90 mm and are available up to 500 watts. maxon also offers an extensive selection of gearheads, encoders, tachometers, and control...

When you choose Composite Motors, you gain access to a reliable and forward-thinking partner in the realm of fractional horsepower motors. Our products are designed to endure, ensuring that your systems operate at their best for years to come. Join us in embracing the power of innovation and quality, as we continue to shape the future of fractional horsepower motors together.

More Fractional Horsepower Motor Manufacturers

The categorization of FHP motors is usually relative to the size of the frame and the total amount of fractional horsepower in the motor. For example, 42, 48, and 56 size frames are still considered to be FHP motors even if the motor has more than one horsepower. In general, though, for small electric motors to be classified as FHP motors, they must have a power output of only 746 watts or less.

Applications

Fractional horsepower motors find widespread applications across various industries and everyday devices due to their compact size, efficiency, and versatility. In the industrial sector, these motors are commonly used in small machinery and equipment, such as pumps, fans, blowers, conveyors, and compressors. Their ability to deliver adequate power while occupying minimal space makes them ideal for automation and manufacturing processes, where precision and reliability are crucial.

In the automotive industry, fractional horsepower motors play a vital role in various components, including power windows, windshield wipers, seat adjustments, and HVAC systems. Their precise control and compact design make them essential for enhancing the convenience and comfort of modern vehicles.

In the medical field, meanwhile, fractional horsepower motors are extensively used in medical devices such as infusion pumps, blood analyzers, and dental equipment. Their low power consumption, reliability, and quiet operation are particularly advantageous in medical settings, where precision and patient comfort are top priorities.

Fractional horsepower motors also find applications in the HVAC (Heating, Ventilation, and Air Conditioning) industry, powering components like fans, compressors, and air handlers. Their energy efficiency and ability to handle varying loads make them valuable in maintaining temperature control and ventilation in residential, commercial, and industrial settings.

Furthermore, in the consumer electronics market, fractional horsepower motors are commonly found in various appliances, including refrigerators, washing machines, vacuum cleaners, and kitchen mixers. Their compact size and low noise output are particularly desirable in household devices, where space and user comfort are significant considerations.

Moreover, fractional horsepower motors are extensively used in the aerospace and aviation industries, driving small actuation systems, aviation control surfaces, and robotics. Their lightweight yet powerful performance makes them well-suited for these applications.

In summary, fractional horsepower motors have found a place in a broad range of applications across diverse industries. Their reliability, efficiency, and compact design have made them indispensable components in industrial machinery, automotive systems, medical devices, HVAC equipment, consumer electronics, aerospace, and aviation applications, among others. As technology advances, the scope for their applications is likely to continue expanding, driving innovation and enhancing efficiency in numerous domains.

History

The basic technology used in fractional horsepower motors, the induction motor, was invented by the scientist and inventor Nikola Tesla in 1888. Despite the fact that he invented the means to power motors, it wasn’t until 1915 that use and production of FHP motors began to become more widespread. This increased use of FHP motors corresponded with the growing installation of electric utilities in urban areas. The washing machine, for example, was one of the first consumer applications of FHP motors. Engineers and manufacturers began using and installing FHP motors in appliances so rapidly that, by 1920, the United States alone housed over 500,000 functioning FHP motors.

Following World War II, FHP motor manufacturing experienced a new surge as the demand for consumer goods increased. Since that time, demand for these environmentally-friendly motors has continued to grow and the number of applications that they can be used for continues to rise. For example, most automotive systems, power tools, small machines and appliances use FHP motors. Because of the practicality of FHP motors, they continue to be incredibly popular. In 2017, experts estimated that the European FHP market was worth around 4.5 billion USD.

Design

When designing or selecting a fractional horsepower motor, manufacturers must first decide on a number of different details, based on their applications. Such details include required maximum and minimum torque, required maximum and minimum speed, speed variability, speed reversibility, how quickly the motor moves from powered down to full power, and whether or not to include brushes.

Horsepower is a measurement of how much work a motor can do in a given amount of time.

Torque is the degree of angular force that the motor can endeavor to produce.

Speed, in this context, refers to the rate at which the motor turns.

FHP motor manufacturers also think about your motor type, bearings, enclosure, mount, power supply, and thermal protection.

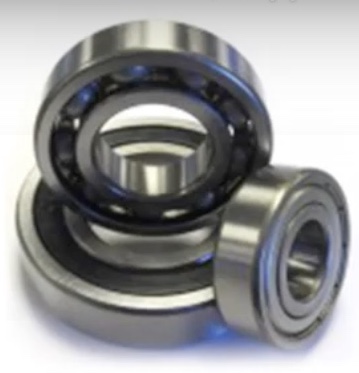

Bearings must match the application in both weight capacity and speed/torque capacity. Some are best for heavy duty loads, while others are best for light duty loads. Common choices manufacturers make include ball bearings (for heavy axial loads), sleeve bearings, and needle bearings (for high speed applications).

Enclosures protect the motor from outside influences like corrosion, impact, chemicals, etc. Manufacturers select enclosures based on the size, shape, and protection requirements of the FHP motor.

Power supplies that manufacturers use for FHP motors include single-phase AC power, AC three-phase power, and DC power. Usually, manufacturers go for single-phase power supplies. They carefully select the voltage they will use based on the application requirements, including the location (European markets and the various markets in Asia call for different motor voltages).

Thermal protection is a feature that tells the motor to shut off anytime it reaches a predetermined heat. Manufacturers choose the shut off temperature to be a little under the temperature at which the motor will overheat. The thermal protection mechanisms that manufacturers most often install are manual reset switches and automatic reset switches. As their respective names imply, operators must reset manual switches themselves (after the motor has cooled down), while automatic reset switches will turn the motor back on by themselves.

Manufacturers can customize traits like voltage, number of phases (three-phase motor, single-phase motor, etc.), power supply, and motor frequency.

The size of FHP motors is based on standards that have been established by the National Electrical Manufacturers Association (NEMA). In fact, sometimes FHP motors are called NEMA motors.

Features

In general, FHP motors feature a rotor or rotating shaft, a stator, a field magnet, a coil, an axle, and an enclosure. Since fractional horsepower motors come in so many different types, there are different ways that they can operate. Some are fuel powered, but most of the time FHP motors run on electricity. In addition, some FHP motors run on the power source of magnets.

Electric power makes it easy for these motors to have variable speeds and reversible gears. Because FHP motors are universal electric motors, they can function on alternating current (AC) or direct current (DC). To generate power, both AC and DC FHP electric motors use magnets that provide motion. The magnets react with the current, causing rotation.

Types

Small electric motors use 745.7 watts of power. They are durable and reliable and have four basic parts: two battery leads, a cylindrical enclosure, an axle, and a nylon end cap.

½ HP motors are FHP motor types that run on about 373 watts of power, which is half of one horsepower.

¼ HP motors are FHP motors that run on one quarter of a horsepower, which is approximately 186 watts.

AC motors run on alternating currents, or currents that flow in the opposite direction. They are typically electric motors, and they use either AC induction (AC induction motor) or synchronous (AC synchronous motor) motor powering methods.

DC motors run on direct currents and these currents flow in one direction only. Generally electric motors, DC motors can use variable speeds.

Variable speed FHP motors can direct the speed of the motor to increase or decrease as desired. The low horsepower makes the speed and motion easier to control since control in an FHP motor is so precise.

Electric powered fractional motors are built with a rotor (AC motor rotor or DC motor rotor), axle, coil, field magnet, and enclosure. To help conduct electrical currents, some FHP electric motors also have internal brushes.

Brushless FHP motors are costlier because they require an external power supply to transfer their current.

Fuel-powered fractional horsepower motors use exhaust valves and a fuel chamber to generate power instead of a coil and magnet. FHP fuel-powered motors, also called internal combustion engines, can be fueled using gasoline or diesel depending on the design.

Permanent magnet motors are FHP motors powered by permanent magnets (PMs) located in their rotor assemblies. There, the assembly stays in line with the stator magnetic field as it rotates. PMs create motors with more power, higher torque (even when running at a low speed), higher torque efficiency, and no slip. The only disadvantage of permanent magnet motors is their cost; because manufacturers often make the with rare earth magnets, they can be quite expensive.

FHP induction motors contain not permanent magnets, but only electromagnets. Induction motors employ a coil wrapped around a stator in order to modulate electrical current. Said modulation jumpstarts, or induces, a rotating magnetic field that revolves around the rotor.

FHP single-phase motors are popular as inexpensive, efficient, and trustworthy motors. They run using a single-phase AC electric power. In other words, they get all of their voltages in unison from one source.

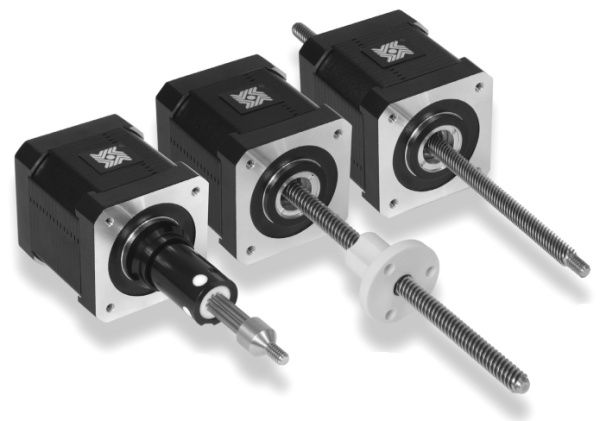

FHP gearmotors reduce motor speeds using a combination of the motor and a gear head.

Sub-fractional motors, also known as micro motors, are extremely small fractional horsepower motors. Typically, they are found in items like electric toothbrushes or remote controlled toys.

Advantages

Fractional horsepower motors face competition from a variety of alternatives, ranging from larger industrial motors to alternative technologies. One primary competitor is the higher horsepower motors that are used in heavy-duty industrial applications. These larger motors can handle more significant loads and provide higher output power but come with the drawback of increased size, cost, and energy consumption. For smaller, less demanding tasks, fractional horsepower motors offer distinct benefits. Their compact size and lower power output make them ideal for applications where space is limited and energy efficiency is crucial.

Another competitor is manual labor, particularly in scenarios where low power requirements can be met by human effort. However, fractional horsepower motors have a clear advantage in terms of consistency, precision, and fatigue resistance. They can tirelessly perform repetitive tasks without human error or the need for rest, leading to increased productivity and reduced operational costs.

In recent times, there has been growing interest in alternative technologies, such as piezoelectric actuators and magnetic levitation systems, which have specific niche applications. While these technologies offer unique advantages, fractional horsepower motors continue to dominate in many practical and diverse settings due to their reliability, ease of use, and cost-effectiveness.

The benefits of fractional horsepower motors over these alternatives are evident. First and foremost, their lower power consumption translates into energy savings, making them environmentally friendly and cost-efficient over the long term. Their compact size allows for seamless integration into various devices and machinery, enabling efficient use of space and facilitating portability. Additionally, fractional horsepower motors have a proven track record of reliability and durability, requiring minimal maintenance and offering an extended operational lifespan.

Furthermore, the versatility of fractional horsepower motors makes them widely applicable across a broad spectrum of industries, from household appliances to medical devices and automotive applications. Their ease of installation and user-friendly operation ensures quick setup and broad accessibility, even for non-experts. These motors also boast a competitive price point, making them an attractive choice for manufacturers looking to keep production costs in check.

In conclusion, fractional horsepower motors stand out as an excellent choice in scenarios where higher horsepower motors, manual labor, or alternative technologies are not the most suitable options. Their efficiency, reliability, versatility, and cost-effectiveness make them a preferred choice for a wide range of applications, driving their continued popularity in the market.

Accessories

Fractional horsepower motors can be complemented by various accessories that enhance their performance and usability in different applications. Couplings, for instance, play a crucial role in connecting the motor shaft to other rotating components, allowing efficient power transfer and compensating for misalignments. Motor bases and adaptor bases, meanwhile, provide stable mounting platforms and adaptability, ensuring proper alignment with the driven equipment, reducing vibrations, and promoting optimal motor operation. Furthermore, brush holder caps, especially in DC motors, shield and protect the brush holders from contamination, ensuring consistent electrical current conduction to the rotor. Rectifiers are additionally valuable additions for AC motors, converting the power supply to DC and enabling precise speed control and reversibility. Finally, dust covers protect the motor’s internal components from dust and debris, maintaining efficiency and preventing damage in harsh environments.

Brakes can be added to provide controlled stopping or holding capabilities, essential for applications requiring rapid deceleration or position holding. Additionally, foot mounts offer sturdy bases for securely fixing the motor to specific locations on machinery frames or equipment housings. Determining the need for these accessories depends on various factors, including the type of motor, speed control requirements, environmental conditions, and compatibility with the driven equipment. Consulting with experts and considering application-specific demands will aid in making informed decisions.

To acquire these accessories, interested individuals can reach out to local motor dealers, distributors, and industrial suppliers. Many manufacturers specializing in motor-related products offer these accessories through their websites or online marketplaces. Seeking guidance from motor experts or engineers can provide valuable insights to identify the most suitable accessories for particular applications, ensuring optimal motor performance and longevity.

Standards

In the United States, several organizations and agencies play a crucial role in setting standards for fractional horsepower motors to ensure safety, efficiency, and performance consistency. Notably, the National Electrical Manufacturers Association (NEMA) is a prominent standards-setting organization in the electrical industry, including electric motors. NEMA establishes guidelines and performance standards for fractional horsepower motors, covering aspects like design, materials, testing, and efficiency ratings. Additionally, the Institute of Electrical and Electronics Engineers (IEEE) and the American National Standards Institute (ANSI) also contribute to the development of motor-related standards.

The importance of these standards cannot be overstated. They serve as benchmarks for manufacturers, ensuring that fractional horsepower motors meet specific criteria for quality and performance. Compliance with these standards promotes interoperability and compatibility between motors and various equipment, reducing the risk of malfunctions and accidents. Furthermore, adhering to these standards fosters consumer confidence by assuring that motors are safe, reliable, and environmentally friendly.

Using fractional horsepower motors that do not meet these standards can lead to various consequences. First and foremost, non-compliant motors may pose safety hazards, as they might lack necessary protective features or fail to meet electrical safety requirements. Such motors could result in electrical fires, shocks, or other accidents that endanger people and property. Additionally, non-compliant motors may be inefficient, leading to higher energy consumption and increased operational costs. In industrial settings, this could affect productivity, lead to downtime, and increase maintenance expenses.

On the other hand, utilizing fractional horsepower motors that meet established standards offers several benefits. Compliance ensures that the motors meet specific efficiency levels, resulting in energy savings and reduced environmental impact. These motors are designed for reliable and consistent performance, increasing the overall reliability of the systems they power. Additionally, using compliant motors aligns with regulatory requirements, allowing businesses to avoid penalties or legal issues. Moreover, using standardized motors simplifies the replacement process and ensures compatibility with existing equipment, promoting ease of maintenance and reducing downtime.

In conclusion, organizations like NEMA, IEEE, and ANSI set standards for fractional horsepower motors in the United States, serving as essential guidelines for manufacturers, consumers, and regulators. Compliance with these standards guarantees safety, efficiency, and performance consistency, while non-compliant motors may lead to safety hazards, inefficiency, and increased operational costs. Utilizing fractional horsepower motors that meet established standards provides energy savings, reliability, regulatory compliance, and compatibility benefits, making them a preferred choice for a wide range of applications.

Things to Consider

No matter your motor type, it is not guaranteed to run well, unless you work with a high-quality manufacturer you can trust. There are a lot of options out there, and we know that can be overwhelming. That is why we have put together a list of reliable, experienced fractional horsepower motor manufacturers for you to consider. You will find their information, complete with profiles, sandwiched in between these informational paragraphs. Before checking them out, we recommend you take the time to put together a list of your specifications. This will help you more quickly determine whether or not a potential supplier provides the services you need. This will also make your conversations more focused and productive when you talk to your potential suppliers. After you have written out your list, take a look at those companies we have listed. Pick out three or four you believe to hold the most promise, then reach out for a quote. Talk to each of them at length about all your requirements, including budget, timeline, standard requirements, delivery preferences, and post-delivery support preferences. Once you have spoken with each of them, compare and contrast your conversations, and pick the right one for you. Good luck!

Air Cylinders

Air Cylinders Assembly Machinery

Assembly Machinery Ball Bearings

Ball Bearings Electric Motors

Electric Motors Fractional Horsepower Motors

Fractional Horsepower Motors Friction Materials

Friction Materials Linear Actuators

Linear Actuators Linear Bearings

Linear Bearings Linear Slides

Linear Slides Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services