Miniature motors are small electric motors that convert electrical energy into mechanical energy. Miniature motors are used where larger motors cannot fit. A small motor ranges from 1.24 inches in length and 0.511 inches in diameter. At 8,000 rpm, it is capable of 2.5 W of output power. Read More…

Since 1963, Dart Controls has been designing and manufacturing some of the world’s most reliable variable speed motor drives, controls and accessories for electric motors. Through continuous innovation, a relentless dedication to the industry, and a commitment to high quality products and dependable delivery Dart Controls has retained the leadership position it established over 60 years ago.

When reliability and power are a must, the universal motors you find at ElectroCraft can operate with high efficiency, low voltage, and at a low cost. Applications that our universal electric motors serve include robotics, packaging, automotive, and medical equipment. Electric motor products include the CompletePower™ Plus Universal Drive, complete with a user-friendly configurable interface....

American Electric Motors is a full service shop offering total sales & repair service, from A.C. motors, pump motors & servo motors to 5,000 H.P. D.C. motors. We stock & sell all types of new motors, pumps & brakes, plus our large inventory of used & remanufactured electric motors can save you thousands.

For custom-designed and -manufactured gear motors, contact us. We’ve been doing this business since 1958. So, for either permanent magnet AC motors or shaded pole induction DC motors, we’re the ones to get in touch with. Our website contains a downloadable motor design sheet—we welcome you to use it.

When you choose Composite Motors, you gain access to a reliable and forward-thinking partner in the realm of fractional horsepower motors. Our products are designed to endure, ensuring that your systems operate at their best for years to come. Join us in embracing the power of innovation and quality, as we continue to shape the future of fractional horsepower motors together.

More Miniature Motor Manufacturers

A miniature motor is constructed with Neodymium magnets, priceless metal brushes, and a moving-coil rotor with a Rhombic-wound winding for maximum winding density. Miniature motors have five ratios ranging from 4:1 to 1,118:1, a torque capacity of 0.35 Nm continuous and 0.53 Nm intermittent, and a matching 0.511-inch planetary gearhead. Many micro motors are made with lighter materials to maximize the power-to-weight ratio.

Types of Miniature Motors

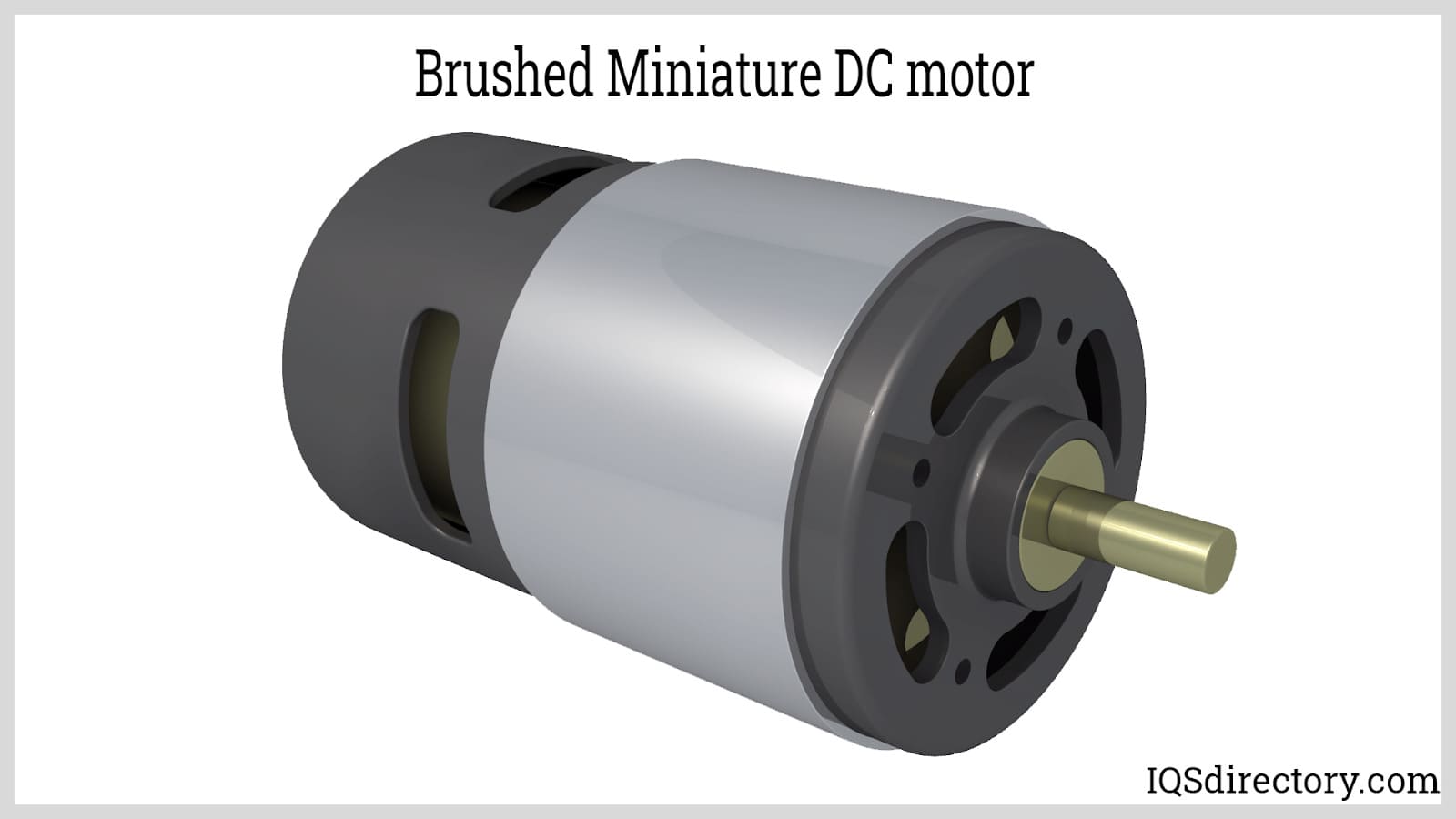

Brushed Miniature DC Motor

A brushed DC motor is ideal for both large and small devices. A brushed DC motor produces low friction, low starting voltages, negligible iron losses, great efficiency, good thermal dissipation, and a linear relationship between torque and speed. These tiny motors are primarily made to offer outstanding speed-to-torque performance with minimal joule heating.

Miniature Brushless DC Motor

Miniature BLDC motor technology maintains the slotted and slotless motors' outstanding performance. These motors have excellent position control, superb speed, outstanding torque, and extended life. While slotted DC brushless motors employ stators with windings and lamination, slotless Brushless DC motors use an ironless cylindrical loop created using a similar winding technique.

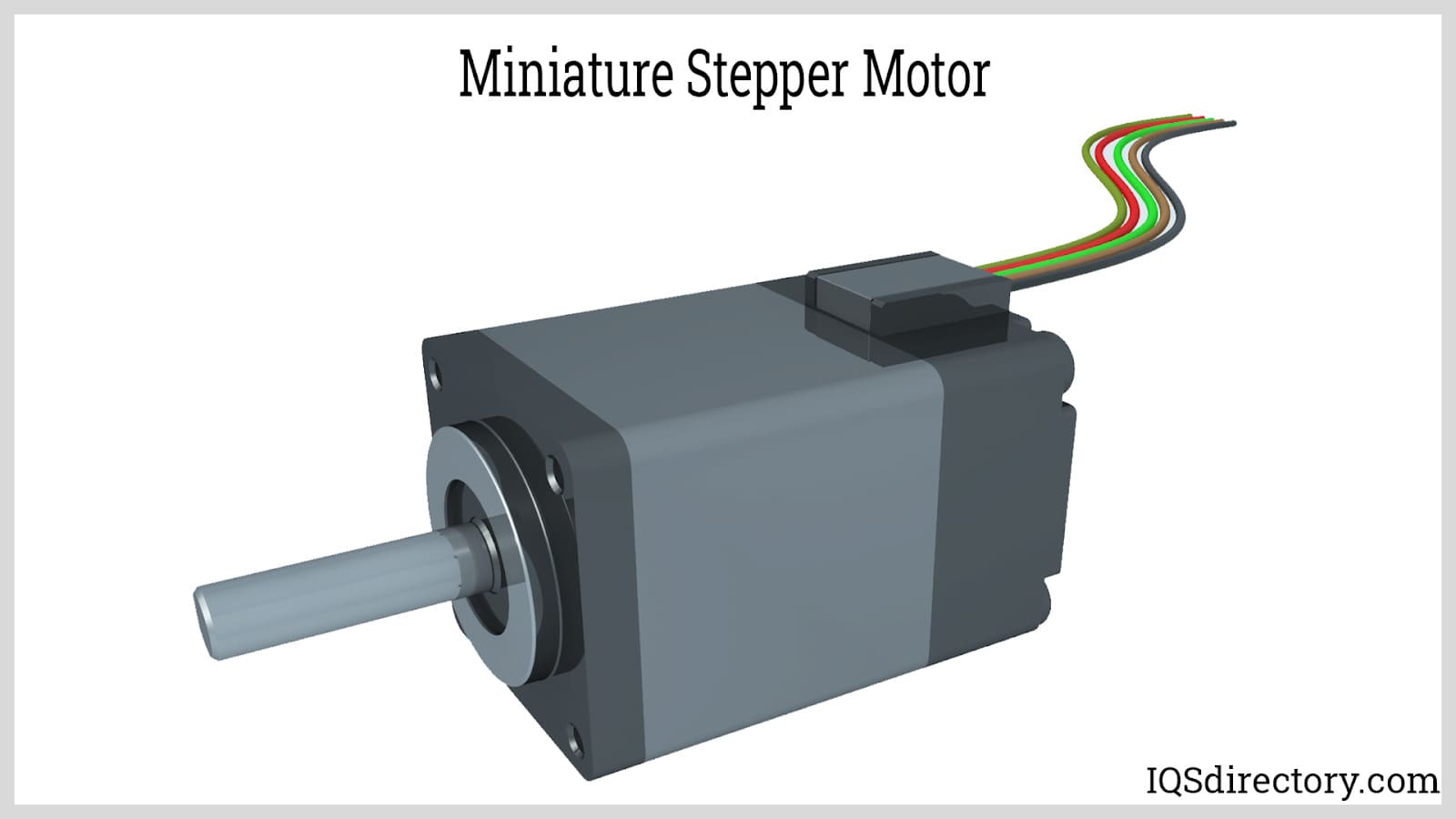

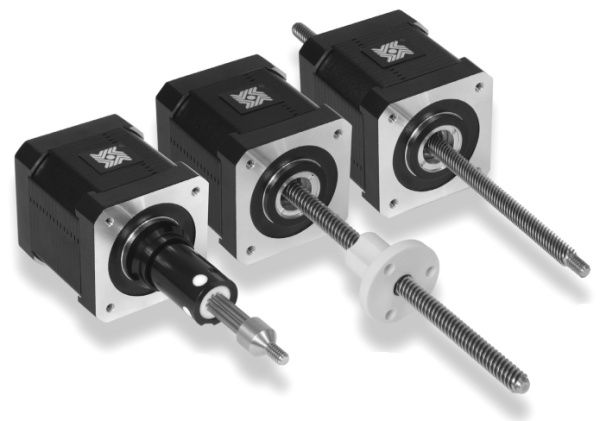

Miniature Stepper Motor

Any other permanent magnet stepper motor cannot be used with these motors. These motors' cutting-edge technology enables a very fantastic dynamic motor act. The single thin disc magnet creates a shorter magnetic circuit. This means a miniature stepper motor won’t lose as much iron. That allows for higher acceleration compared to traditional steppers. Miniature stepper motors are ideal for applications that require rapid incremental motion.

Miniature Motor Features

The miniature motors features include the following.

- High Efficiency

- Speed Variability

- Speed Control

- Low Price

- High Quality

- High Reliability

- Communication

- Dimensions

- Light Weight

Applications of Mini Motor

- Industrial robots: Miniature motors help Industrial robots perform quick, accurate movements. Improved industrial robots are created as motor efficiency and power density increase. Robots become lighter, more nimble, and more energy-efficient, allowing for both improved mobility and quicker productivity. This reduces cost of ownership for automation solutions.

- Pick and place assembly: Since the 1980s, manufacturers have used pick-and-place (P&P) or surface-mounted technology (SMT) equipment to assemble semiconductors and electronic components. A robot arm picks up a part and accurately attaches or positions it on a circuit board. Miniature motors are a great solution because they are compact enough to fit in the robot and enable rapid, accurate movements. Assembly systems can complete millions of cycles, so the motor needs a long service life.

- Material handling: Materials must be moved around during industrial operations. This automation solution may include a simple robotic arm or a sophisticated network of machinery wired for material handling tasks like stacking and sorting. The system can transport goods with the least amount of assistance from humans to storage or the producing location. Material handling automation guarantees minimal waste and effective utilization of inventories. Since they take up less room and contribute to energy conservation, miniature motors can frequently take the place of other motor types in these solutions. They help complete tasks that require precise and delicate handling.

- Yarn winding machinery: In the textile industry, yarn winding machines are frequently used to wind yarn for processes like knitting or weaving. To avoid tangling (which halts production and damages material), yarn winders must accurately position and guide the yarn. Small motors can supply the accurate motions needed.

- Conveyor system: Conveyor systems rapidly transfer components or materials. Conveyors are essential to the production process in many industries. High-performance micro motors allow Conveyor systems to transport heavy loads using a smaller space. The reduced motor size opens up more design possibilities.

- Modern tiny motors can now handle various demanding requirements of industrial automation applications. Engineers may be confident that as motor technology improves, it will be able to deliver the power required for practically all applications that depend on precise miniature motions.

Choosing the Correct Miniature Motor Supplier

To ensure the most beneficial outcome when purchasing miniature motors from a miniature motor supplier, it is important to compare several companies using our directory of miniature motor suppliers. Each miniature motor supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each miniature motor company website using our patented website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple miniature motor businesses with the same form.

Air Cylinders

Air Cylinders Assembly Machinery

Assembly Machinery Ball Bearings

Ball Bearings Electric Motors

Electric Motors Fractional Horsepower Motors

Fractional Horsepower Motors Friction Materials

Friction Materials Linear Actuators

Linear Actuators Linear Bearings

Linear Bearings Linear Slides

Linear Slides Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services